Split tray sorter

KEY SPECIFICATIONS

Capacity

14.400 items / hr

Product characteristics

< 750 x 550 x 200 mm

< 5 kg

Product range

Fashion, e-commerce items

Flexible layouts

Enable optimal use of space

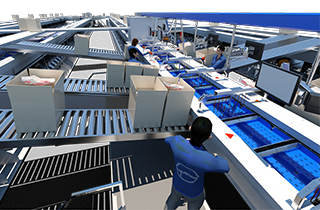

The split tray sorter is a tray-based bomb-bay sorter, developed to handle flat goods such as packets, books, garments, and accessories. The split tray sorter is able to sort outgoing goods for shipment as well as returned goods for restocking. It has a characteristic oval-shaped conveyor on which the trays circulate. Our “open oval” design allows operators to work in the open space inside of the oval. Products are transported along with the sorter on trays that discharge the items directly into stations through a bomb bay door mechanism. Products can be inducted into the sorter trays manually or automatically.

This sorter drops the items into roll containers or bags, this is not suited for the most fragile items. When looking for a solution that also handles fragile items, the slide tray sorter or the LR-sorter might be a better fit.

We offer two tray types for our split tray sorter: the split tray (bomb-bay) and single door tray.

Sorter specifications

| Sorting capacity: | 7.200 - 14.400 items / hr (17.600 items / hr with smart distribution) |

| Products: |

Envelopes, e-commerce, fashion, packages, accessories

|

| Product dimensions: |

Min.: 50 x 50 x 2 mm Max.: 650 x 450 x 220 mm |

| Product weight: |

Min: 0.01 kg Max: 5 kg |

| Infeed options |

Automatic or manual infeed |

Product options

Specification sheet

Download our product specification sheet by filling out the form below.

Station options

Based on the shipping medium, we provide chutes with an open end, to directly sort into the carton, tote or trolley. We also provide chutes with a cut-off option. The end of the chute can be either closed or opened, offering a buffer when exchanging a full or completed exit medium. These stations are often used in e-fulfillment or fashion projects.

Like the cartons, totes, or trolleys, these stations are selected based on the shipping medium. If all products are to be shipped in cages or bags, we can directly sort into these mediums. This saves time as operators don't have to worry about moving products from the chute into the bags or cages. However, these stations are quite high and could affect the height of the sorter. Typically, these stations are found in projects involving small parcels or envelopes.

BENEFITS

Flexible layouts

Improve efficiency

Reduce errors

We're ready to grow your business

CASE STUDIES