Induction options

Home » Induction options

We offer manual or automatic induction for our slide tray sorter, LR-sorter and split tray sorter. These two options are selected based on your process, required capacity or amount of automation.

Manual induction

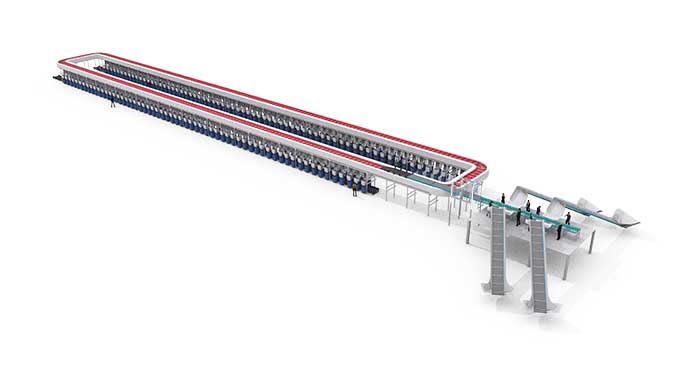

Manual induction can be easily recognised by the direct induction of items into the trays. The items can be scanned by using a scanner at the induction station or by using an omni scanner. The omni scanner identifies items in the tray. This relieves the operator of the task to scan the product before inducting it and could increase the induction capacity. We have a fully documented whitepaper on the different factors that influence the induction capacity and how to improve the induction capacity. However, if you're working with cartons filled with the same SKU's manual scanning could be sufficient. The first product will have to be scanned, but all following products can be inducted without scanning. We often see this process at retail companies. The image above shows a manual induction zone where operators scan the products before putting them directly into the sorter.

Product leaflet

More information about the split tray sorter can be found in our leaflet.

Automatic induction

On the other hand, we offer automatic induction for our sorters. This can be achieved by using a belt conveyor as infeed. The image below shows an example of automatic induction. Operators put the items on a conveyor, on which items are automatically scanned before entering the sorter.