Lietuvos paštas is ready for increased parcel throughput

Home » Lietuvos paštas is ready for increased parcel throughput

Lietuvos Paštas (Lithuanian Post) is seeing a staggering increase in the amount of parcels sent. Over 800.000 customers rely on their efficient and reliable handling of these parcels. To continue providing a fast and errorless shipping process the company needed to transform its parcel flow. Kastytis Valantinas, Director Of Operations at Lietuvos Paštas was part of the project team that was designing this new flow and explains how they found the answer to their challenges.

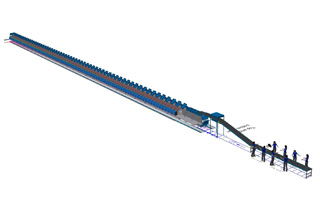

SD-sorter under construction

The rise in parcels is nothing new. In the past few years e-commerce has been driving growth in the amount of parcels sent. However, this has been pushed to a whole new level during the COVID-pandemic in 2020. According to the Pitney Bowes Parcel Shipping Index[1], global parcel volumes reached 131.2 billion in 2020. A total of 4,160 parcels were shipped per second!

Changing product scope

Kastytis Valantinas, Director Of Operations explains: “The largest part of e-commerce shipments include various dimensions of parcels. Therefore the average parcel size in our operations processes has decreased over the years as the number of e-commerce shipments grew. We needed to adjust our processes to allow efficient handling of this new product scope.

For this project we preferred to work with an experienced partner. We chose Equinox as an integration partner as they provided the most promising system design and were able to handle the full scope of LP demands.“

Conveyors to crossbelt sorter with parcels

Separated parcel flow to reach maximum capacity

“The project included a solution for our courier service and parcel flow” says Kastytis Valantinas. “We decided to separate products into two flows. By choosing a separated flow, we increase the throughput and efficiency of our hub without compromises.”

By looking thoroughly at the product mix that passes through the hub, the right sorting systems could be selected. By sketching a few different flows, it soon became clear that it would be most beneficial to create a separated flow. Two flows were defined: a small parcel flow for large envelopes and parcels up to 5kg and the courier flow with mostly large and heavy items up to 30kg. These will be sorted respectively by a SD-sorter and a crossbelt sorter.

Sorting elegance

At full throttle the system will be capable of handling small parcels 340.000 items per day. This has defined the way Lietuvos Paštas is handling the increase in parcels in Lithuania. Not only the efficiency of the system is worth mentioning, but it also has a few very characteristic looks.

For starters, the small parcel sorter is designed with the unique Lietuvos Paštas yellow that immediately catches the eye when you enter the hub. But the system also features a unique infeed. To fully use the available space, this infeed does not use the standard incline belt. The incline is replaced by a spiral conveyor that elevates the parcels to the sorter.

Getting the most out of the available space

The SD-sorter that handles the small parcels has an open layout. As space was limited for this sorter a smart solution was needed for the sorter and the infeed. This layout is known as the extra wide oval. It allows operators to work in the heart of the machine. This allows sorting to stations located on the inside and outside of the machine. By doing so, we maximise the number of stations in the given area. This system has 381 exits, each consisting of a chute that drops the parcels in postal bags.

Six operators feed the sorter at the infeed. They place items on a pocket belt. This feeds the parcel into the sorter via the spiral conveyor. This solution allows a throughput of 10.000 items per hour.

Crossbelt sorter infeed

From truck to pallet

In another hall the courier process starts within the trucks. Telescopic conveyors are used to unload parcels directly from the truck. These conveyors are directly linked to the automatic infeed of the sorter. Parcels ranging between 5 – 30 kg are weighed, volumized and scanned in the trays. Smaller items can be put in trays to enable sorting over the same system.

The items are sorted to 32 exits, each using chutes to buffer the items. These exits each have their own tablet which helps to further sort the items by hand to up to 8 pallets per exit.

Confidently facing the future

The new solution allows Lietuvos Paštas to confidently face the increasing amount of parcels, both small and large. The smart distribution program optimised their efforts in supporting their customers. With this new solution, the company has started a new chapter and is ready for the future!

Local partnership

The decision to work with a local partner turned out even more beneficial than imagined. “Looking back, our choice for a local partner was crucial. Even though we started with the system design before the COVID pandemic, a large part of the installation was carried out during lockdown. As Equinox is located in Lithuania as well, we were able to continue most of the work even during lockdown and travel restrictions.”

Project specifications

- System integration in Vilnius, Lithuania

- Including: SD-sorter, crossbelt sorter, telescopic conveyors

- Capable of sorting 340.000 items per day

- Used to sort small to medium-sized parcels and courier parcel

"By choosing a separated flow, we increase the throughput and efficiency of our hub without compromises."

- Kastytis Valantinas, Director Of Operations