10.000 items per hour and lightning fast installation: The LR-sorter

Home » 10.000 items per hour and lightning fast installation: The LR-sorter

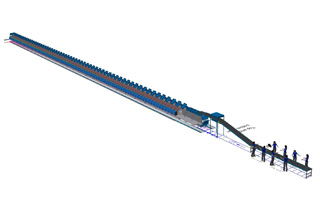

Since its first installation in 2019 the Equinox LR-sorter has proven its use for parcel & e-commerce companies. Customers include Nova Poshta, Ingram Micro, Sending and Grupo Mox. But a lot has changed since 2019. E-commerce and parcel shipping numbers increased and the call for throughput intensified. The time is right for the next step. Get ready for improved throughput, durability, and efficiency. Get ready for the renewed LR-sorter.

This compact vertical sorter is fully modular and designed in standard sections. The standard base can be expanded with advanced options. This includes infeed options, Dimensioning, Weighing and Scanning (DWS), Optical Character Recognition (OCR), or several output designs.

Smooth operation

The most obvious improvement is the increased maximum throughput: 10.000 items per hour. This enables faster operations and improves overall efficiency. This capacity is not just for neatly packed parcels and items we envision in our sorting utopia. This includes the full range of items we send in real-life. Think 10.000 bumpy, lumpy, odd-shaped parcels, padded envelopes, polybags, smalls or packets. The proven slide tray technology enables the sorting of all of the above. This wide application makes it the most versatile sorter for small to medium parcels in the market.

The LR-sorter is not taking half measures. It is designed to reduce strain on your operation and offers a number of operational and ergonomic benefits: it is fast, energy-efficient, quiet (< 70dB) and requires little maintenance.

Goodbye down-time

Our key target was to reduce the time needed to deliver and install the machine. With the need for flexibility and scalability, we offer various expansion options for this sorter that can be installed within 1 day on-site. Installed projects have been executed in less than 3 months after signing the contract. The new and improved version will lower the delivery time even further. Think additional output stations, additional infeed modules or improved scanning options (DWS, OCR).

This starts in our production facility in the Netherlands. It might sound contradictory, but by installing our machines in-house first, we actually save time. We verify that the sorter is fully functional before sending it to the customer. This sorter has become known for its quick installation and expansion. We just need four days to install it on-site.

Our on-site installation has become a lightning-fast plug and play process. All modules can be easily connected due to their modular connection boxes. A money saver for customers that are expanding current installations and already working on-site. This is how we minimise the down-time of the current installation. Or, as one of our first LR-sorter customers put it:

“By installing a new machine on the new location instead of moving the existing one, we have eliminated the downtime during the installation. The existing sorter can still be used while the new LR-sorter is being installed. We realized that this option saves us three weeks of downtime. The solution therefore enables us to guarantee a continuous process.”